Solar Power Gaining Fans

July 21, 2022

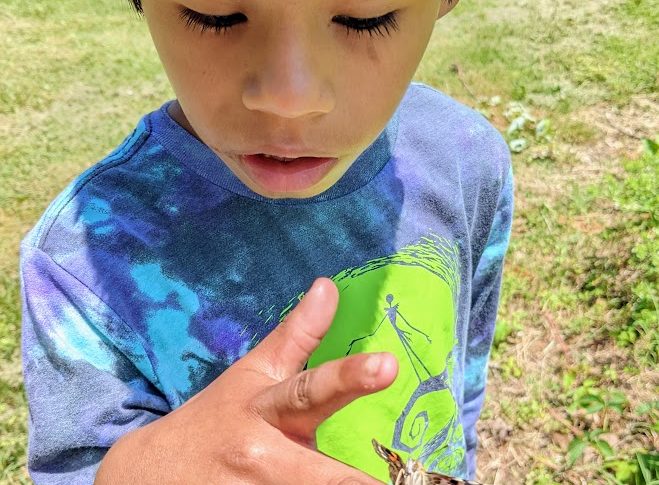

Nature’s Garden

April 21, 2022

BGE Goes Electric—With its Fleet of Vehicles

April 29, 2021

Church Earns National Award

March 11, 2021

Gardening for Health

February 4, 2021

Chesapeake Beach Recognized for Creating a Sustainable Town

October 22, 2020

Composting Businesses Do the Dirty Work for You

October 22, 2020

Annapolis Celebrates Electric Vehicles

September 24, 2020

Stewards Set Sights on Calvert County

September 10, 2020